Erongo Desalination Plant

The first large desalination plant in Sub-Saharan Africa was inaugurated by Areva on the 16 April 2010. The Erongo plant is located near Wlotzkasbaken, 30 km north of Swakopmund. B-4 Diving did all sub-sea works as well as some on shore works.

The works consisted of the following:

Preparing the 900ton caisson and placing in position. The Caisson was constructed in the Port of Walvisbay and the towed 70km north to the location and placed.

The Caisson was the cemented to the ocean floor and a cable to pull the 2 x intake lines as well as the outfall line was installed.The lines are 1,2m diameter and where concrete weigh coated.

B-4 then assisted with the preparation of the shore crossing location by doing sub-sea blasting and excavation.

The lines where then pulled using a custom made linear winch to the caisson where the caisson also acts as an intake chamber for the intake lines.

The lines where then terminated by taking metrologies and manufacturing spool pieces accordingly. Due to the remote location as well as the lack of available plant the spool pieces where installed using buoyancy bags and a lot of innovative planning.

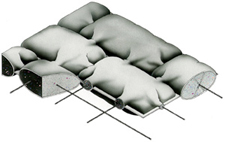

Span corrections where then made by using custom made grout mattresses.

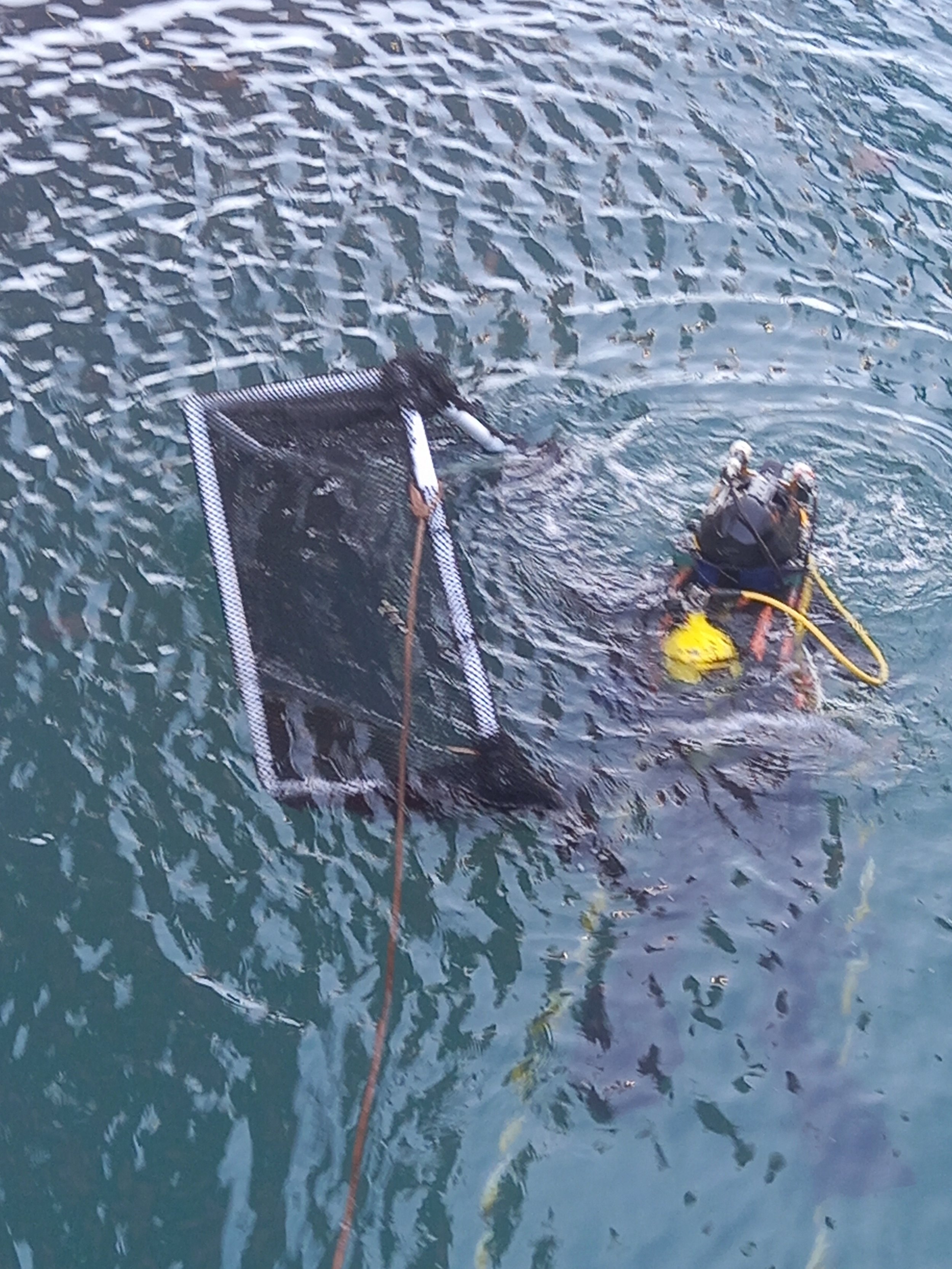

A 40 ton intake screen was the placed on top of the caisson and secured.

All works was completed with no loss time injuries.

900Ton Caisson Floating out of dry dock - Port of Walvisbay

Positioning of the Caisson

Shore Crossing

Refurbishing Berths 1 - 3 Port of Walvisbay. (B-4 Provide Civil Support Services to Steffenutti Stocks Marine)

The works consisted of the following:

Deepening and development of a revetment.

Placing of scour protection in the form of Hydrotext Articulating Grout Mattresses.

Cast of tremmie concrete.

Broco cutting of temporary tubular piles.

Depth survey and inspections.

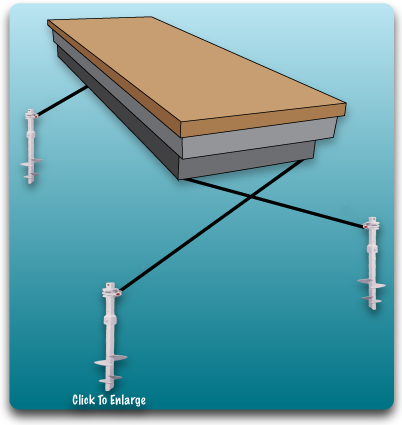

Richards Bay – Floating Wave Attenuator -The works was in support of Stefanutti Stocks Marine.

With barges and ships passing by frequently, creating up to 1,5 meter wakes, this 800 meter long floating wave attenuator made up from 20 by 5 meter pontoons was installed 2012 in Richards Bay, South Africa, to protect the sensitive mangrove area from erosion.

To be able to accomodate the conditions of 1,5 meter waves, 3 meter water level variation, 0,5 m/s current and a muddy and sloping seabed it was designed to use 200 units of Seaflex model 6035 TSBP (6 hawsers, 3,5 meter long per unit with ByPass) along with 3200 meter of our high quality polyester rope, anchored with Helix embedment anchors.

B-4 was responsible for the installation of the Helix Anchors and then install the Seaflex Moorings to the pontoons and joining the pontoons. The Seaflex Anchors was then tensioned. The project completed on program.

Port of Durban - South Africa.

Refurbishing of Maydon Warf 12, Island View 2 and 5.

B-4 gave civil support to Stefanutti Stocks Marine with the refurbishing of these berths.

Island View 5.

The works entailed:Installation of Peri camp system of scaffolding to carry form work of transverse beams connecting piles.

Inspection of revetment and monitoring of sheet piles being driven at toe of revetment.

Installation and recovery of data capturing instruments and recovery.

Island View 2

Placing of score protection under completed berth. This was a change due to the existing structure over the scour previously installed and had failed. The teams had to dredge the materials of the existing scour protection which was an articulating mattress system. Rock was then taken in with custom made barges and dumped.

Geotextile was placed in the area where alongside the quay (approximately 120m long and 20m wide with 1m overlap) in stages class 2 rock was placed of barges.

Maydon Warf 12

Cutting of drain slots using Broco for drainage of accumulated water from the land side.

Continual Maintenance and repair of Floating Docks

The concrete dock are in need of continual maintenance and repair. Our Civil Engineer Miss. Carmon De Beer with her well trained team are tending to this working around the daily operations of the docks and advising the client on prioritizing the repairs.

We had the honor to do a complete Sub-Sea maintenance on the Q7000.

What started with the installation of a oil boom for a STS Bunkering led to install jellyfish traps on the intakes and led to the complete service.

Cleaning of sea water intakes

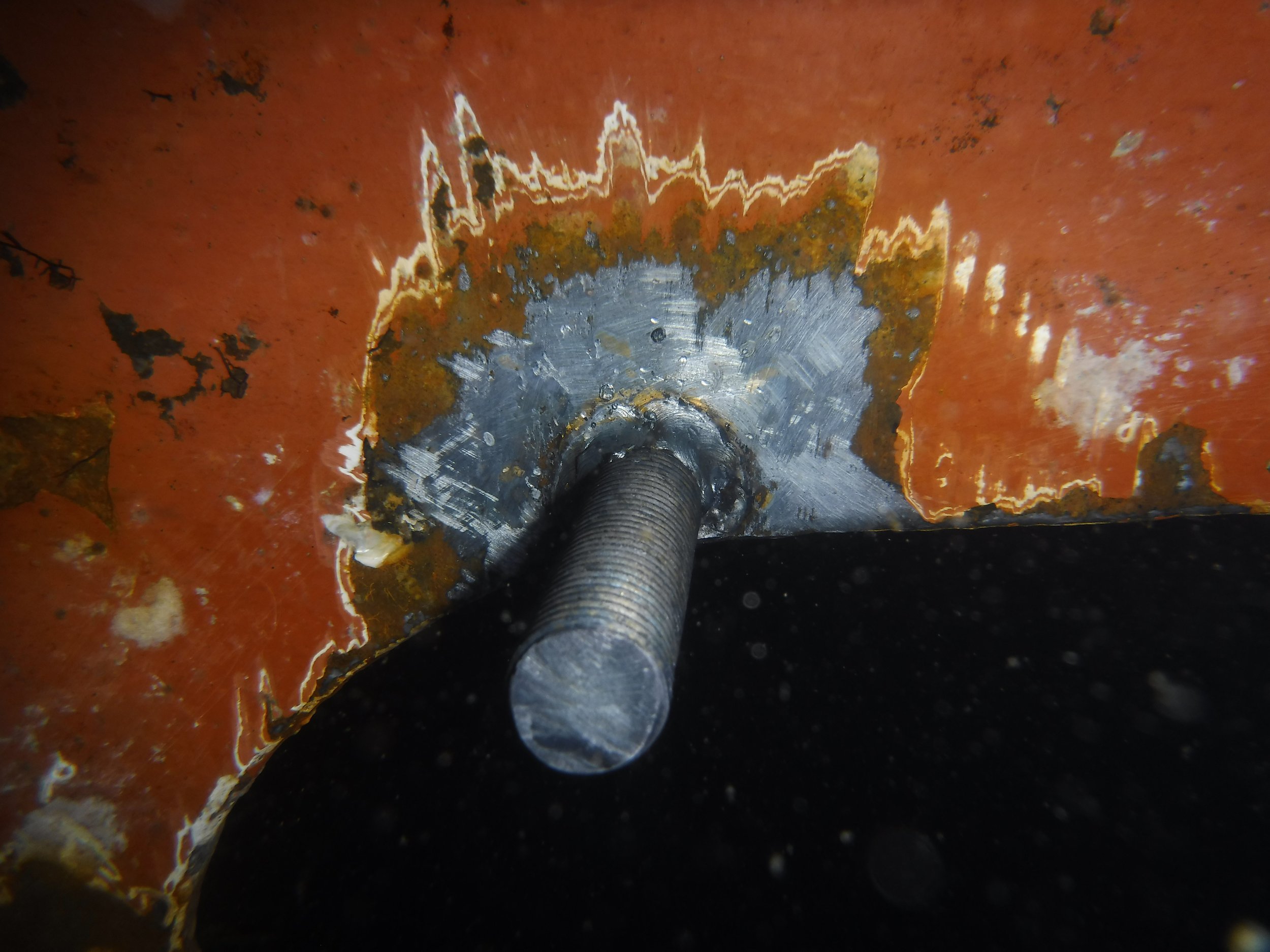

Welding of new studs for gratings

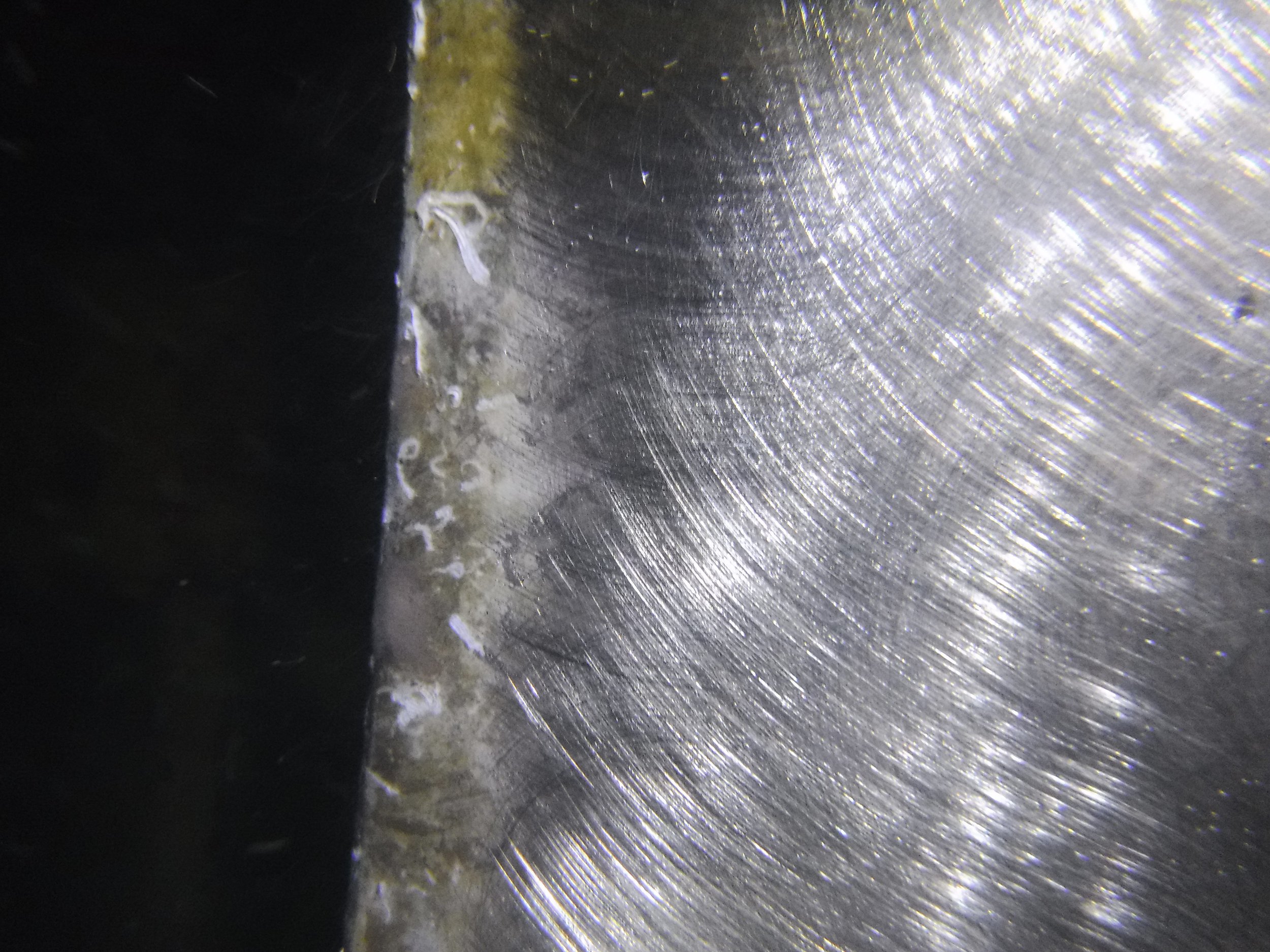

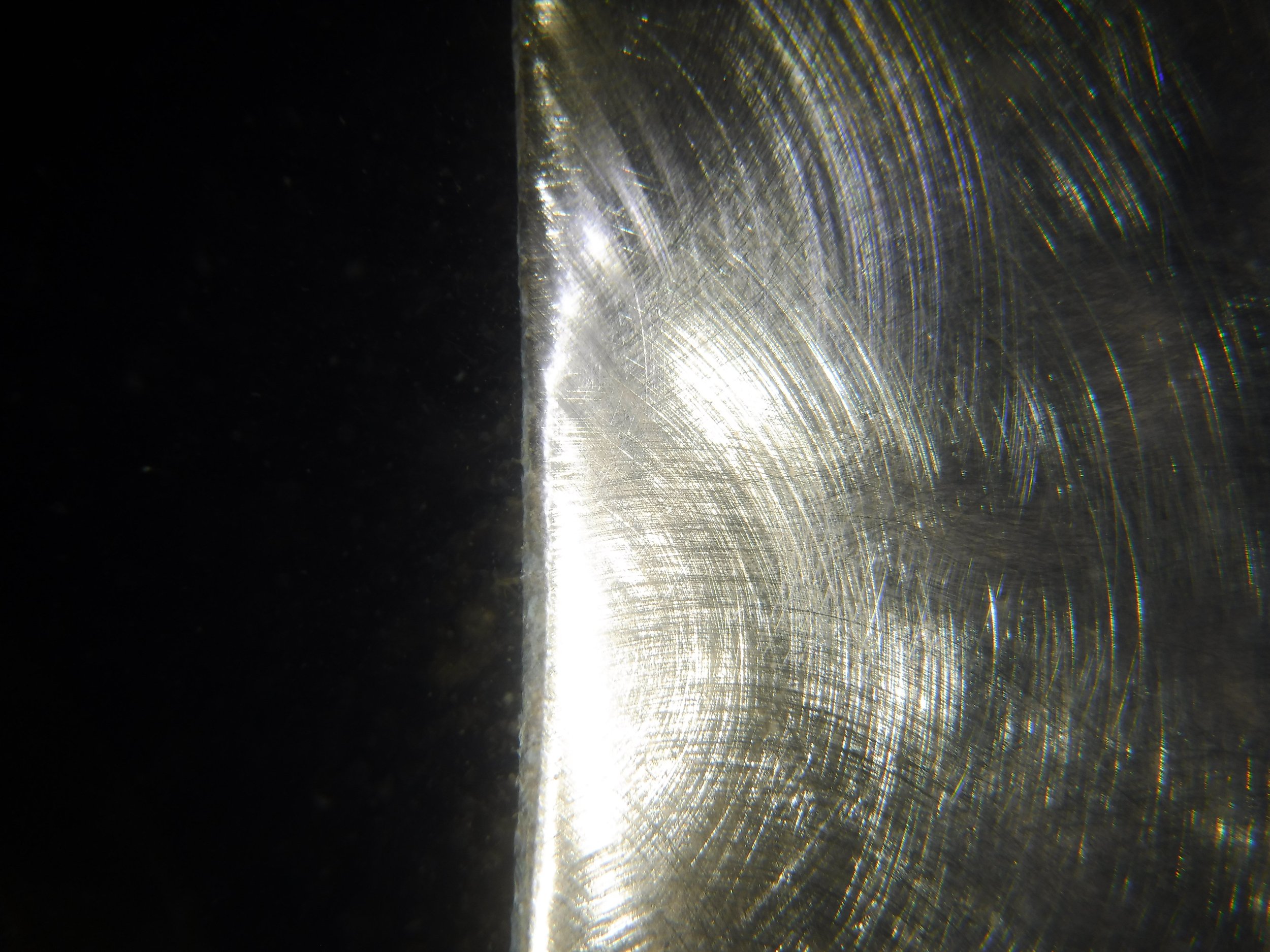

Propeller polish of all thruster units

Complete survey and report on the OMDU

We are proud to have achieved a 100% on the score card from our customer feedback.

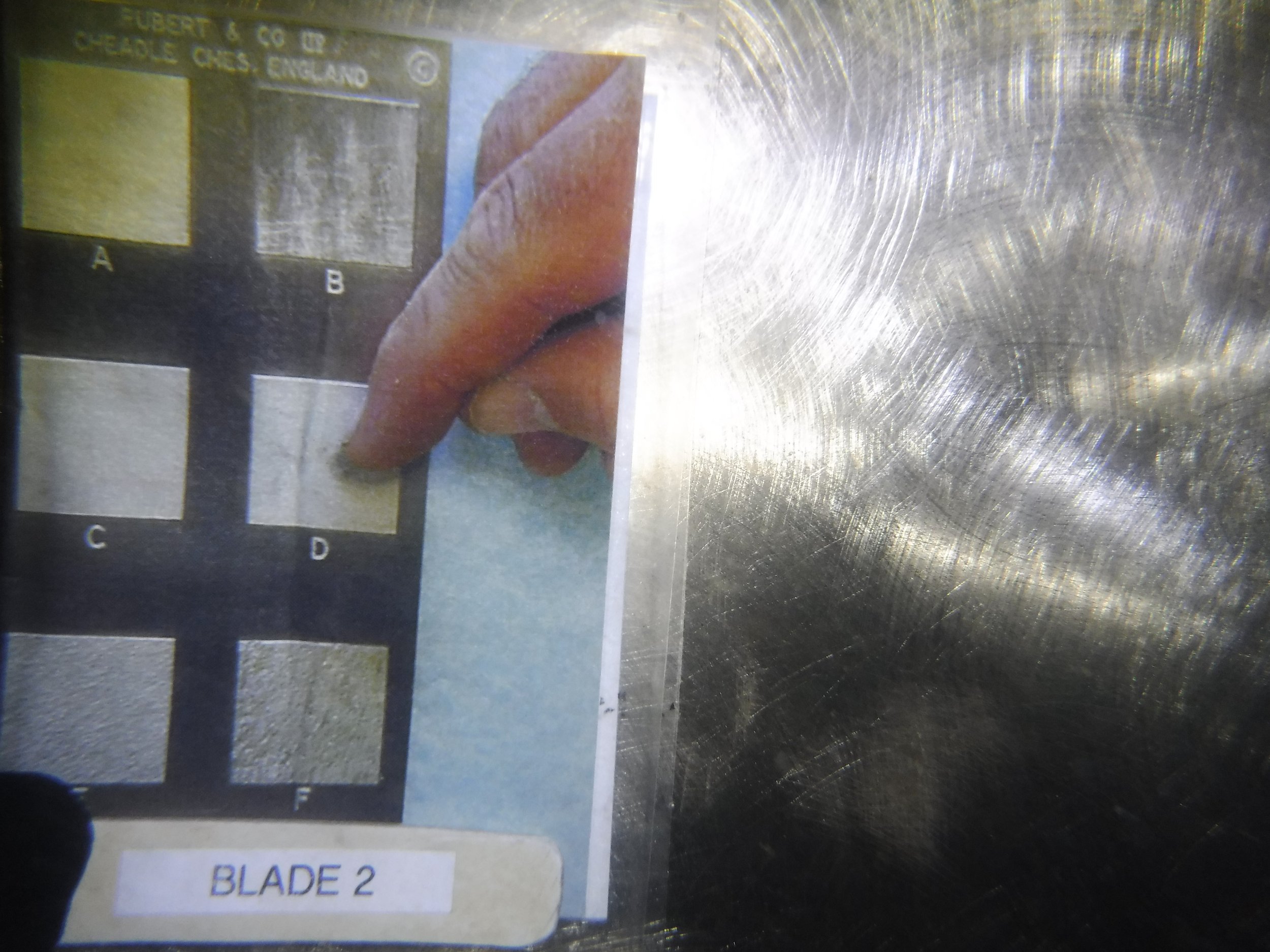

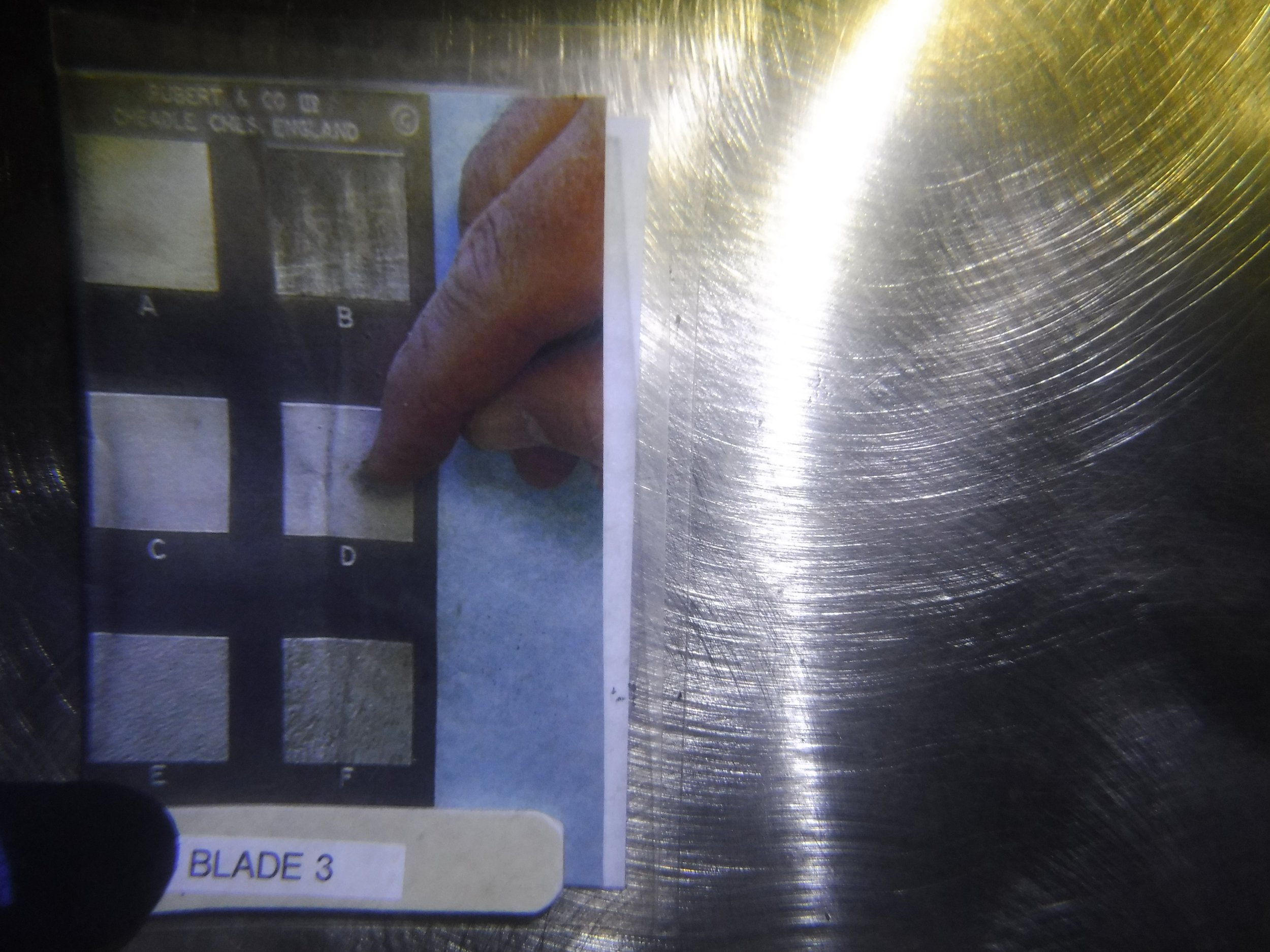

Propeller polishing compared to the Ruperts Scale

The welding of studs. A welding procedure was drawn up for the specific welding of the studs and approved by the client prior to conducting the work.