Ships Husbandry Services

Propeller Polish

Propeller Cropping and Repairs

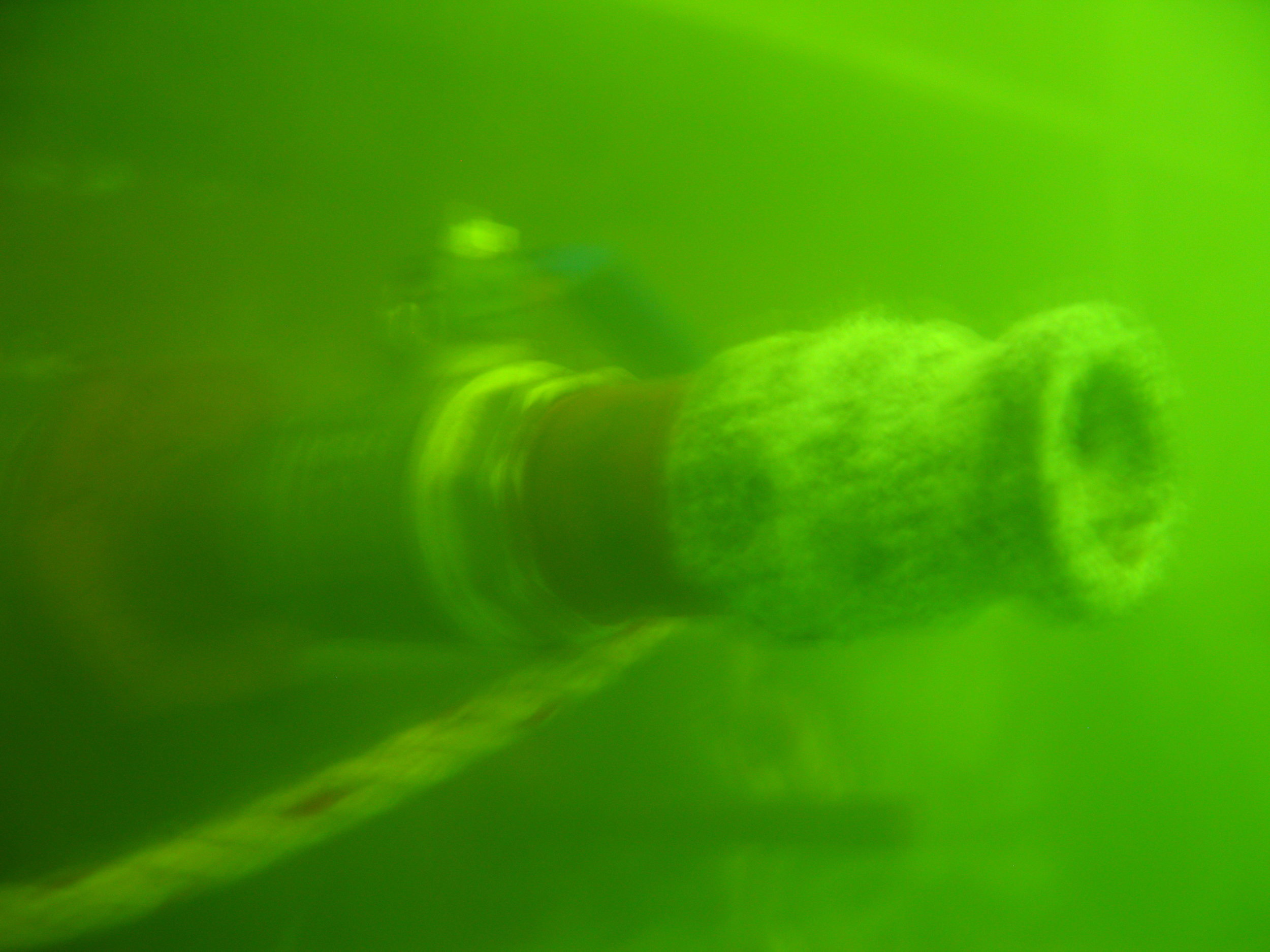

Through hull intake cleaning and blanking

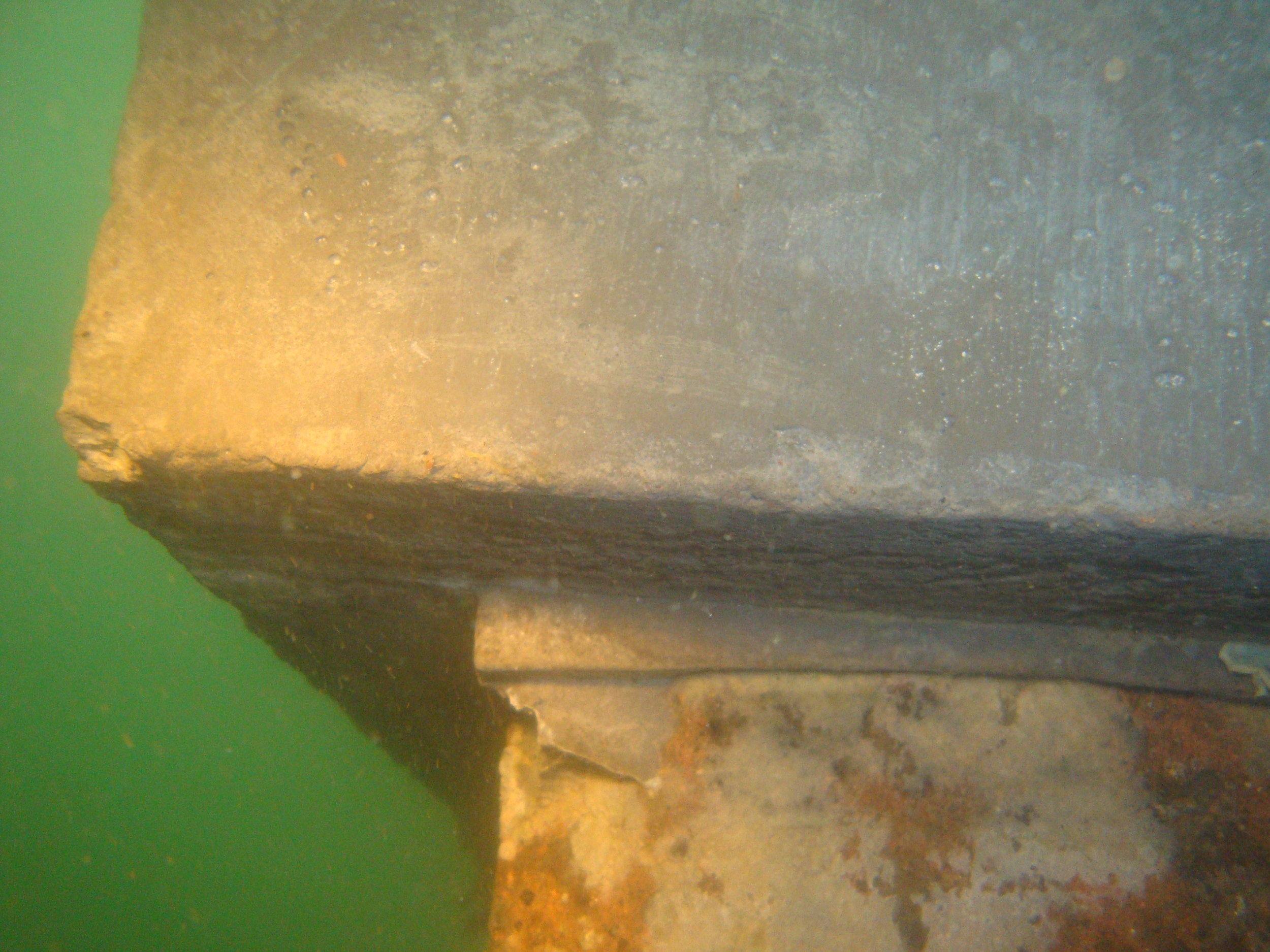

Welding and Ultra Thermal Cutting

Crack arrests and repairs

In water replacing of Sacrificial Cathodic Protection

Video and Still Photography, Inspections and Reporting

Pipe Cleaning

Pipe Coating

Marine Civil Construction and Advanced Concrete Repairs. Accredited Sika Applicators

We have completed repairs on various concrete and wooden structures in the Ports of Luderitz, Port of Walvisbay and Port of Durban

Under soffit and Cope unit repairs

Core drilling

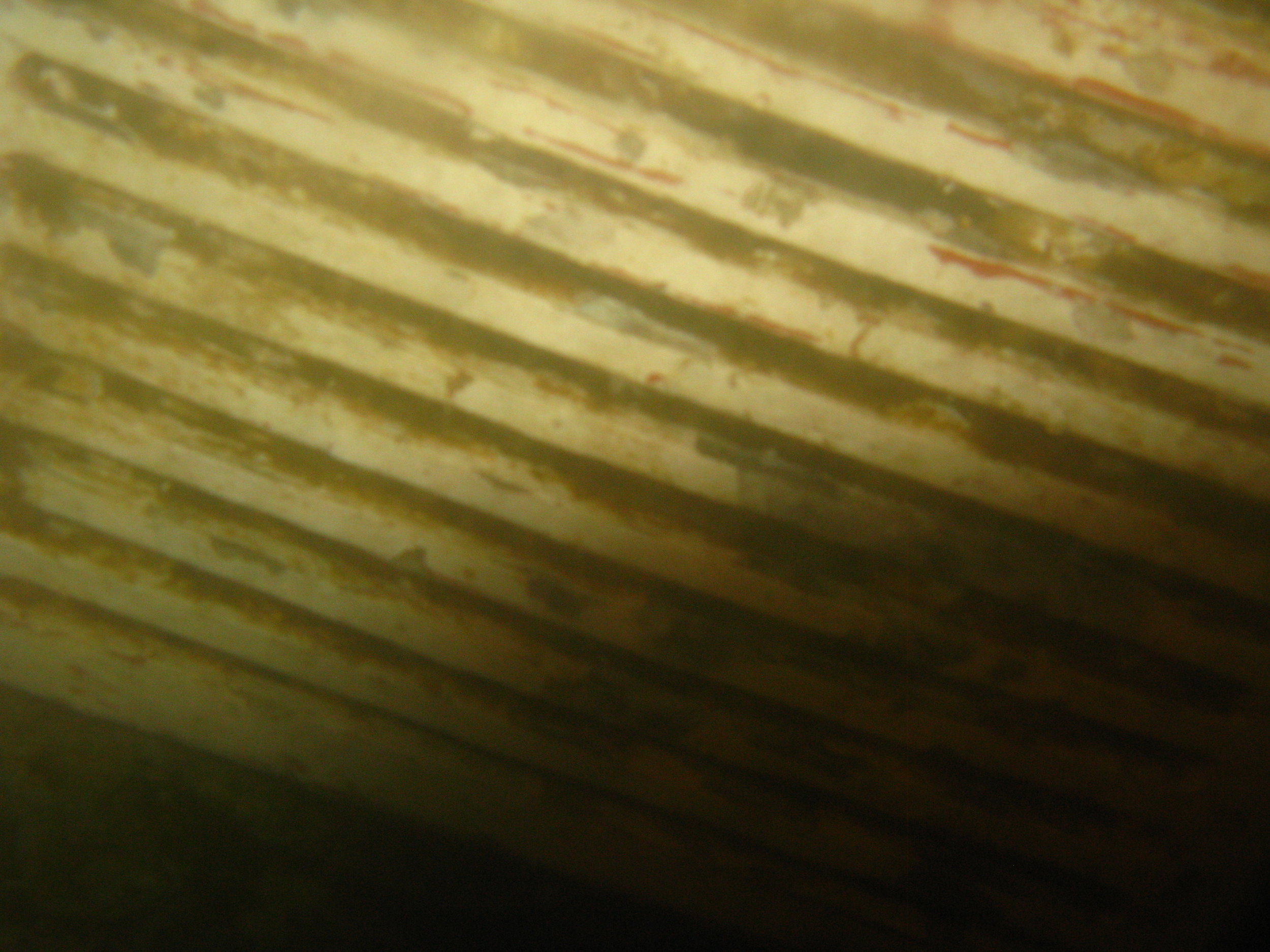

Pile repairs - Concrete as well as wooden structures

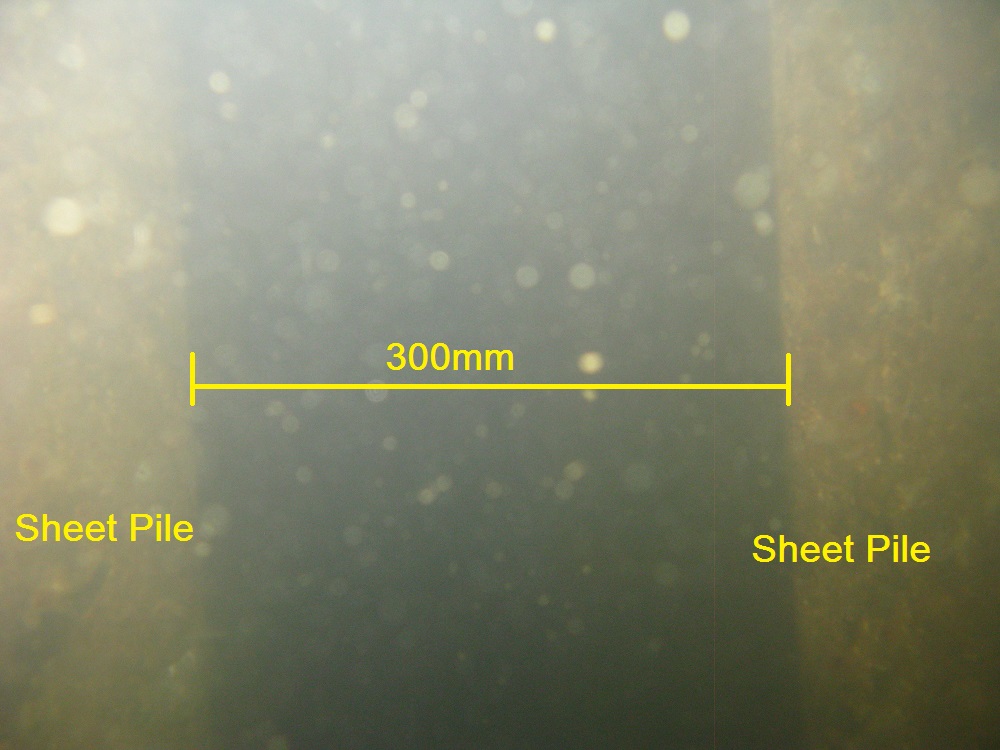

Concrete sheet wall repairs

Concrete jetty and causeways

Installation of articulating grout mattresses for scour protection

Crack injections

NDT on concrete structures

Dredging and Airlifting

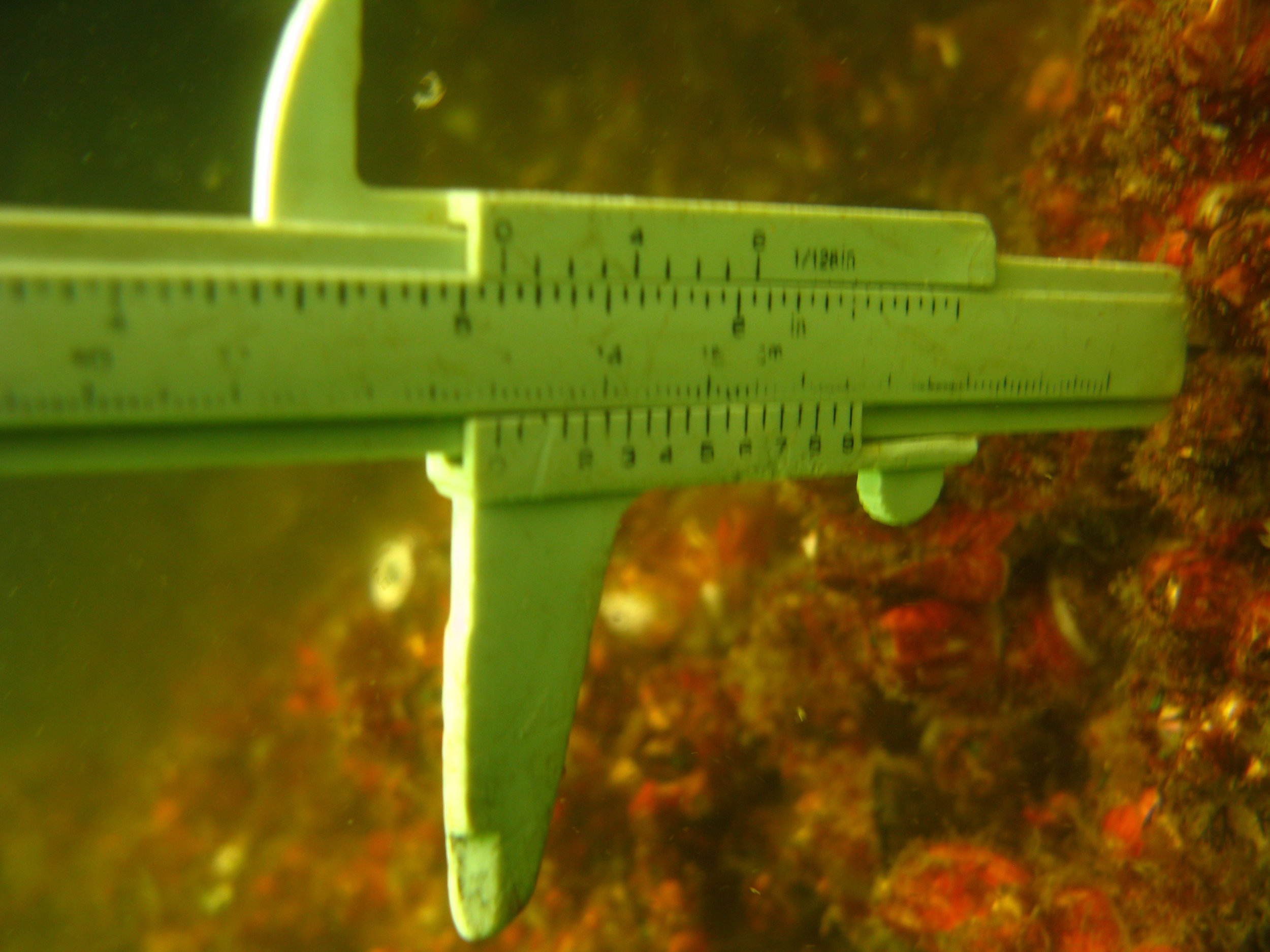

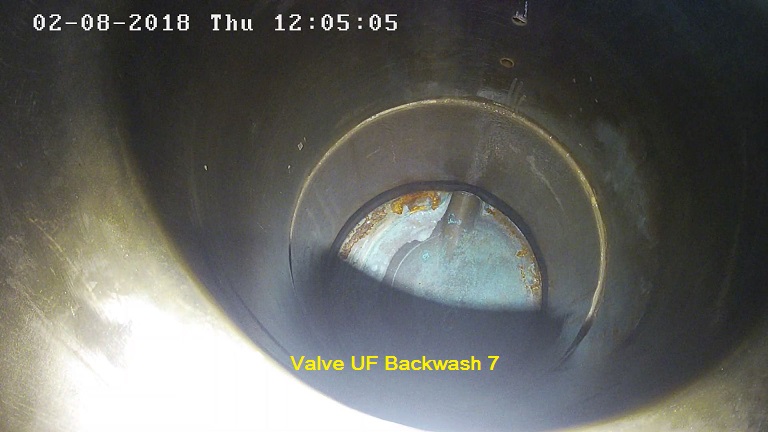

Non Destructive testing

We do regular MPI and UTM thickness surveys. (Both Sub-Sea and surface)

We have built custom robots to do internal pipe line inspections.

Our well trained technicians will be able to assist with all your needs.

Concrete Cutting

Advantages of Diamond Wire Cutting

Diamond wire sawing is an excellent technique for many industries including the construction industry. But what makes this technique so useful and sought-after? Here are just five of the reasons why it’s worth considering seeking diamond wire sawing for your project.

Cuts through almost any material

Diamond wire sawing can be used to cut through almost any material that is softer than diamond itself. This can include almost any material such as stone, masonry, enforced concrete and steel. The sheer strength of diamond wire sawing makes it a common choice for controlled demolition services, such as the safe and quick removal of concrete structures.

Precise technique

In addition to being powerful, diamond wire sawing is a precise cutting technique. It is particularly useful for situations where it is necessary to isolate and cut through thick, reinforced sections of material or shapes, which would be particularly awkward for more traditional cutting techniques. For this reason, wire saws are great for cutting through large sections of reinforced concrete like bridge sections, jetties, columns or beams.

Works in tight spaces

As the section can be reached with a wire, diamond wire sawing is a highly flexible process, making it ideal for use in areas where there is restricted access for more traditional cutting techniques, such as bridge decks. The flexibility of wire saws means that there are very few to zero restrictions on the depth or speed of the cut that they can perform – and they’re fast too.

Can be performed underwater

Often there are scenarios in which cutting is required in environments that are submerged underwater. Handily, diamond wire sawing works just as well underwater as it does above ground. That makes wire sawing an extremely useful technique for businesses such as water and construction companies for maintenance, repair or demolition of marine structures.

Safety Health and Environment

Minimal noise pollution. Dust free cutting

Cost

Costs are calculated of actual work performed and charged per m2 of cutting compared to demolition hammers charged at a rate per Hr.

Experience

B-4 has done cutting in the port of Walvisbay doing minor works sub-sea with the demolition of the cope beam in the Small Craft Harbour for refurbishing.

The teams have completed works on the New Port Extension – Port of Walvisbay. This has been on going and we have cut in the excess of 1000m2. Machines and rails where custom built for the works.

Spill Response And Pro Active Pollution Mitigation

Protecting our environment is our priority

We are proud to be incorporated in the Namport Pollution contingency Plan

B-4 has done numerous spill responses with positive outcome

We have a 12m tug “Ingwegwe” with the polution spill kit on board to contain and manage spills.

We have 800m of certified off-shore boom available for deployment. These booms can handle wind speed of up to 38 Knots. These are ideal for STS bunkering operations at anchorages and OPL operations. Our well trained crew with the “Ingwegewe” will be on standby during the entire operation in the event of a spill. Assuring the ship owners peace of mind.

Training

We are committed to train our personnel in house and external to ensure we provide you with the best service.

We have mentoring programs in place to ensure new employees are brought up to speed and the following our proven procedures.